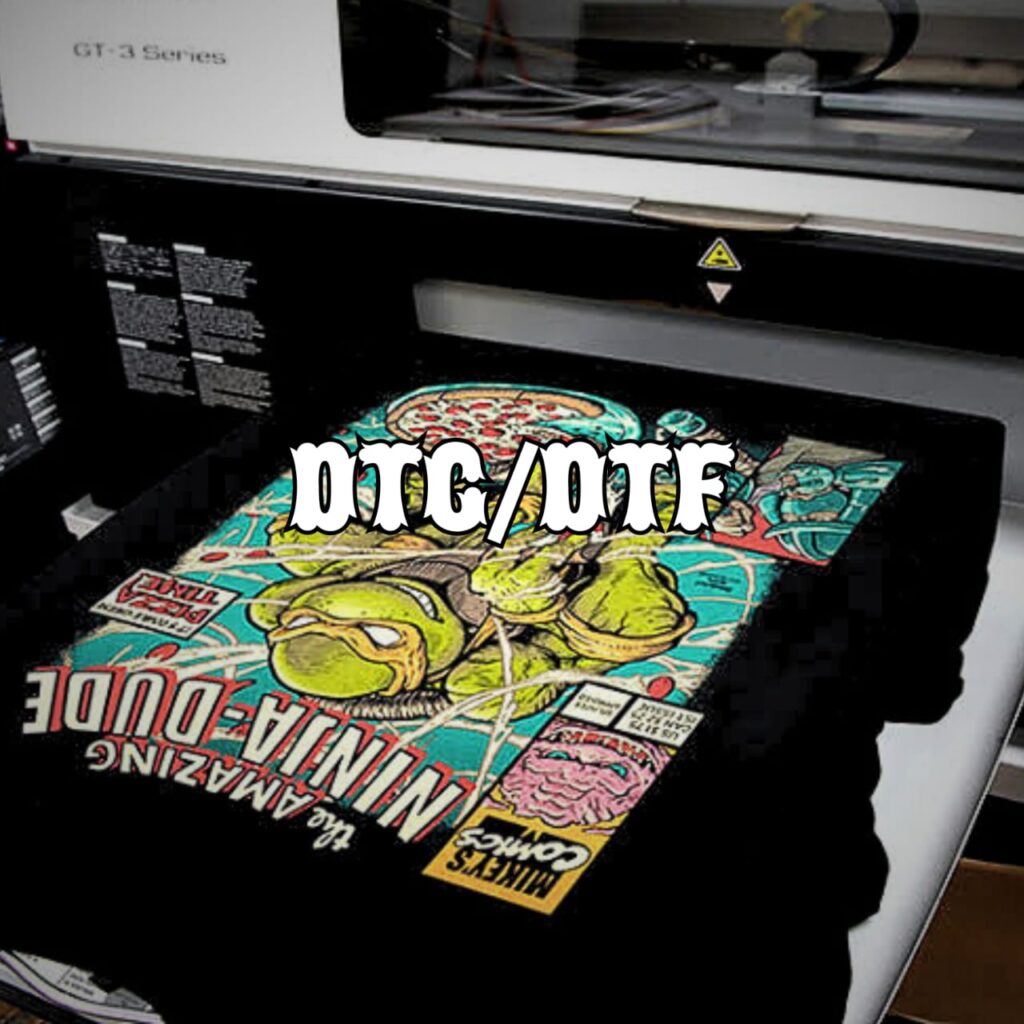

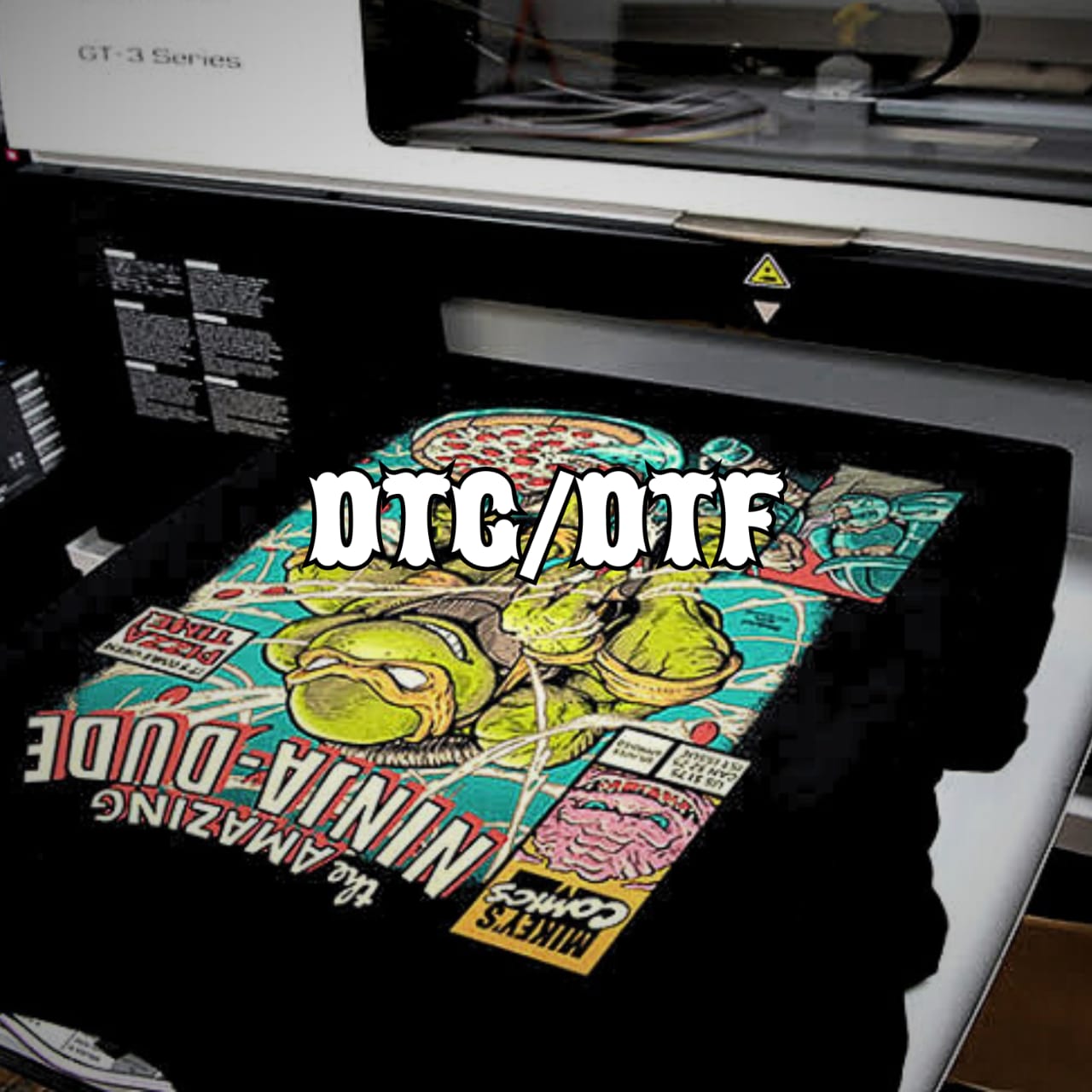

DTG (Direct-to-Garment) and DTF (Direct-to-Film) printing have transformed the apparel industry. Both methods offer fast production, vibrant colors, and unmatched design flexibility. As brands continue to demand detailed and customized artwork, DTG and DTF printing provide reliable solutions that deliver accuracy and quality.

What Is DTG Printing?

DTG printing uses a specialized inkjet printer to apply water-based inks directly onto fabric. The printer sprays the design on the garment with precision, which allows even the smallest details to appear sharp and clear. This method works best on cotton-based apparel and is ideal for small or medium orders that require full-color artwork.

What Is DTF Printing?

DTF printing works differently. First, the design is printed onto a special film. Then, a powder adhesive is applied and cured. Finally, heat transfers the design onto the fabric. This method works on almost all fabric types, including polyester, fleece, blends, and performance wear. Additionally, DTF prints feel soft, stretch well, and remain durable after repeated washes.

How DTG & DTF Help Apparel Brands

Both printing methods bring strong benefits:

- High Detail & Vibrancy: Complex artwork, gradients, and photographic images print beautifully.

- Quick Turnaround: Designs move from digital file to garment quickly, which helps meet tight deadlines.

- Flexibility for Small Orders: Unlike screen printing, you can print even one piece without extra setup.

- Compatibility with Many Fabrics: Especially with DTF, brands can customize everything from hoodies to sportswear.

Why Our Manufacturing Facility Uses DTG & DTF

We use industry-grade DTG and DTF machines to ensure every print looks professional. Moreover, our team checks each garment carefully, which guarantees consistency across bulk and sample orders. Whether you’re launching a fashion brand, producing uniforms, or creating merchandise, we help you achieve premium-quality results. where the substance of your article begins to take shape.

Leave a Reply