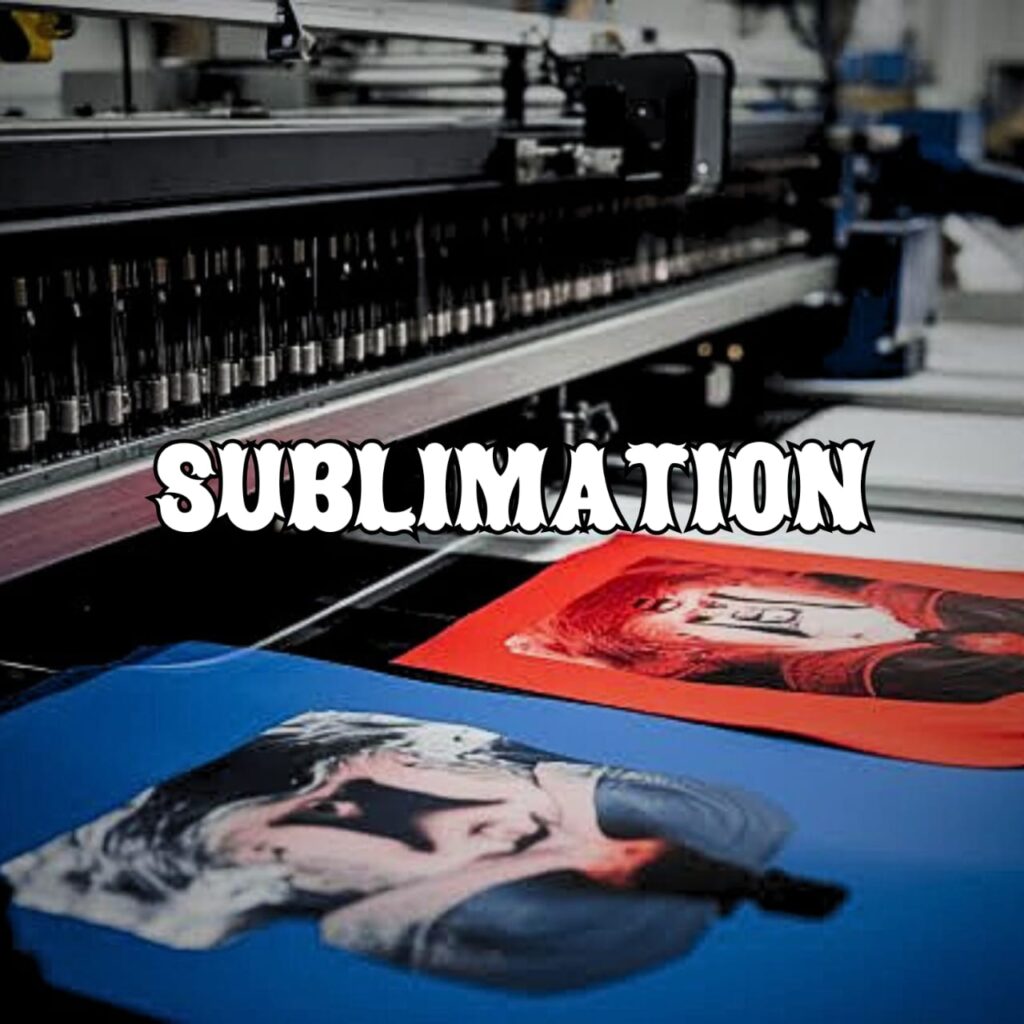

Sublimation printing has become one of the most advanced and reliable printing methods in the apparel industry. It creates vibrant, long-lasting designs that feel completely smooth on the fabric. As brands demand higher-quality custom wear, sublimation continues to grow in popularity.

What Is Sublimation Printing?

Sublimation printing uses heat to turn specialized ink into gas. The gas then bonds directly with polyester-based fabric. Because the ink becomes part of the material, the print stays sharp and bright for a very long time.

How Sublimation Printing Works

1. Design Creation

First, the design is prepared on a computer. Designers finalize colors, patterns, and placement.

2. Transfer Printing

Next, the artwork is printed onto sublimation transfer paper using sublimation ink.

3. Heat Pressing

Then, the printed paper is placed on the garment panel. A heat press machine applies high temperature and pressure. The ink instantly transforms into gas and infuses into the fibers.

4. Final Finishing

After pressing, the fabric cools down, and the colors appear vivid, smooth, and fully permanent.

Why Sublimation Is Perfect for Apparel

- Vibrant Colors: Designs appear extremely bright and photo-realistic.

- No Cracking or Peeling: The print becomes part of the fabric.

- Lightweight Feel: The design feels soft with zero thickness.

- All-Over Printing: Sublimation allows full-panel patterns and unlimited colors.

- Ideal for Sportswear: Polyester jerseys, tracksuits, and activewear look premium with sublimation.

Popular Products Made with Sublimation

- Sports jerseys

- Tracksuits

- Hoodies

- Compression wear

- Fashion tees

- Custom team uniforms

- Event and promotional apparel

Why Brands Choose Sublimation

Brands prefer sublimation because it offers creativity without limits. From gradients to full-body designs, manufacturers can produce detailed artwork quickly and consistently. Moreover, the prints stay fresh even after repeated washing.

Leave a Reply